Motivation and objectives

Composite extrusion processes offer a promising possibility to produce bonded connections between aluminium and steel without forming an intermetallic phase seam with a critical thickness for the composite. The LACE process developed at the institute of materials science is intended to join rigid reinforcing elements made of steel or titanium with an aluminium alloy. The spectrum of profiles that can be produced using composite extrusion presses is to be expanded within the framework of this project and new types of hybrid semi-finished products with increased complexity and at the same time a high proportion of reinforcement are to be produced.

This will be achieved by manufacturing asymmetrical hybrid profiles with thin-walled reinforcing elements. A particular challenge in the production of hybrid asymmetrical profiles is the continuous and firm bonding of the materials. The new tool system will be designed numerically in advance.

A further goal is to increase the lightweight construction potential of the hybrid profiles by using the material combination aluminium and titanium. The resulting composite zones are characterized and numerically determined. In addition, a numerical model will be developed to predict the mechanical properties of the longitudinal press seams and the width of the resulting intermetallic phase seam

Results

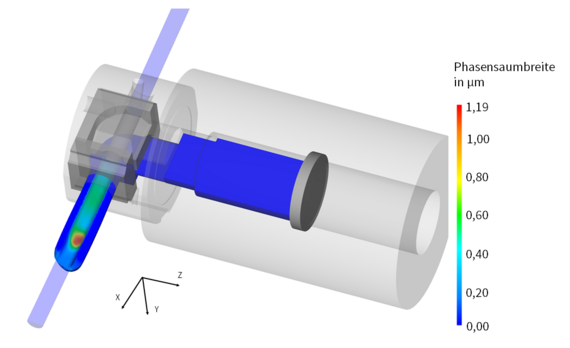

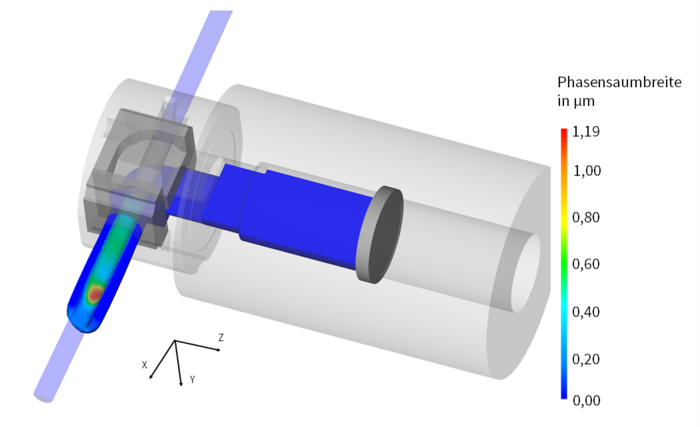

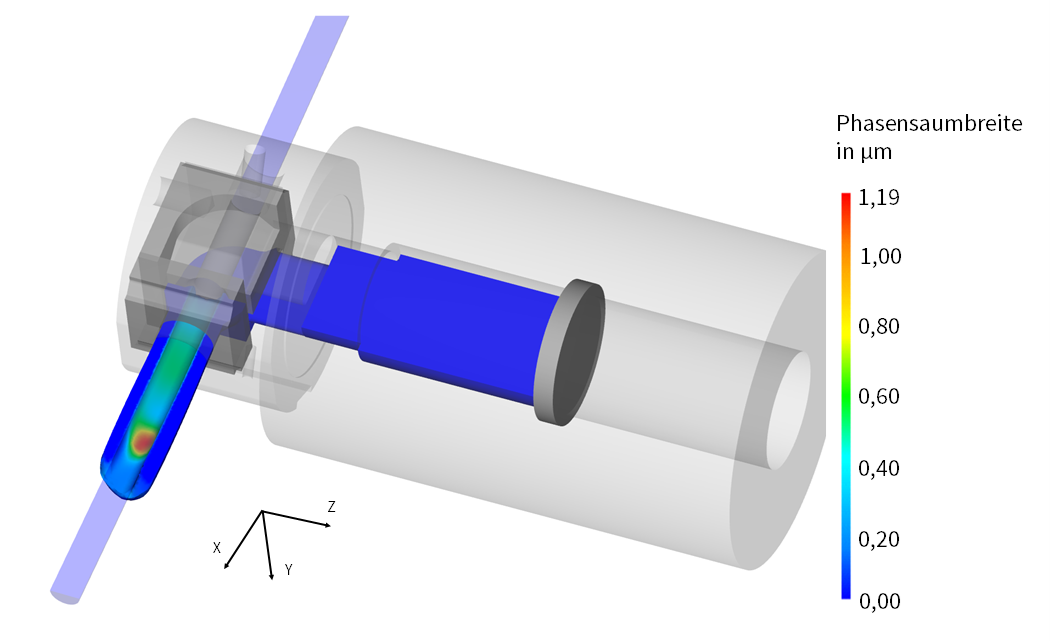

A LACE process, which enables the production of hybrid hollow sections from EN AW-6082 and 20MnCr5 was successfully developed during the first funding period.. Initially, preliminary tests were carried out on a 2.5 MN laboratory extrusion press. The aluminium alloy was deflected through an angle of 90° as a matrix material in the extrusion die and met the steel reinforcing element fed from the side in the welding chamber. In the welding chamber, the bonding zone between aluminium and steel as well as the longitudinal press seams in the aluminium were formed. In order to describe the bond formation of aluminium and steel in the form of intermetallic phases numerically, model tests were carried out and the results were implemented in the FE simulation using a phenomenological model. Figure 1 shows the simulated phase seam width for the 2.5 MN process.

For the transfer of the process to an industrially relevant scale of the 10 MN extrusion press, substantially changes were made to the tool system, which were designed by means of the numerically calculated material flow. The animation shows the 10-MN tool system, which is characterised by a better guidance of the steel tube in the mandrel part.

The hybrid hollow profile is shown in Figure 2, when exiting the 10-MN tool. The modular tool concept allows the production of hybrid profiles with a reinforcement content of up to 34 % by volume.

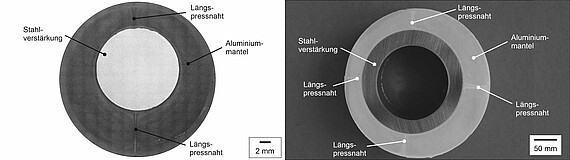

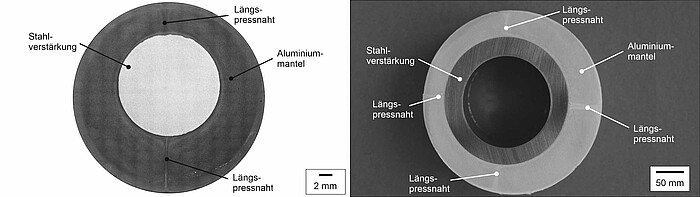

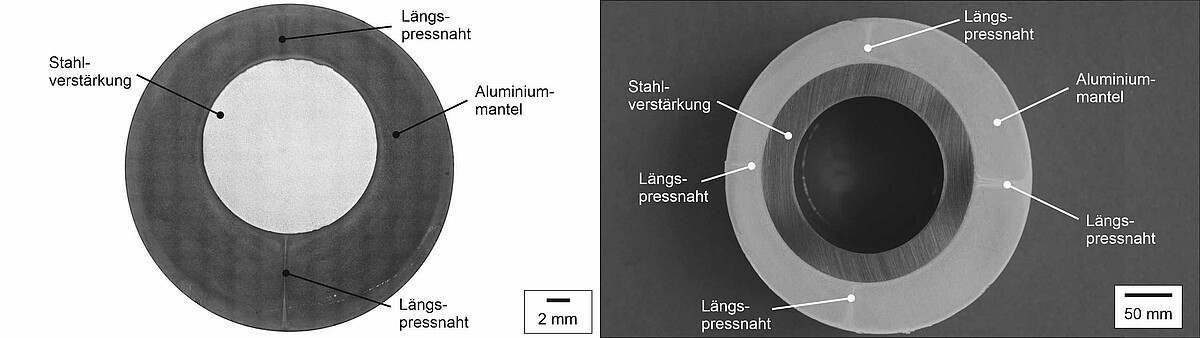

The cross section shown in Figure 3 shows the position of the steel pipe in the composite. In addition, the four longitudinal press seams produced can be seen.

Current work and outlook

The influence on the material flow by the modification of the tool geometry is currently one of the main research areas. The aim is to achieve a reinforcement content of up to 51 % by volume. In addition, investigations into the influence of the alloy constituents of the reinforcing element on the formation of the bond are being carried out. Various case hardening steels such as 20MnCr5 and C15 as well as the stainless steel X5CrNi18 10 are used to determine their influence on the bond quality. In addition to the composite quality, the quality of the longitudinal press seams is currently being characterised in order to derive a calculation model which the longitudinal press seam quality can be numerically viewed with in the future . The investigations on joining aluminium with titanium are planned for initial laboratory-scale tests in order to produce asymmetrical hybrid profiles. The tool system for this is currently being developed and the material flow is being investigated by FE simulations. The bonding of the materials and the distortion of the thin-walled reinforced profile pose new challenges.

Publications

Subproject leaders

30823 Garbsen

30823 Garbsen

30823 Garbsen

Staff

30823 Garbsen

30823 Garbsen

30823 Garbsen

30823 Garbsen

30823 Garbsen

30823 Garbsen