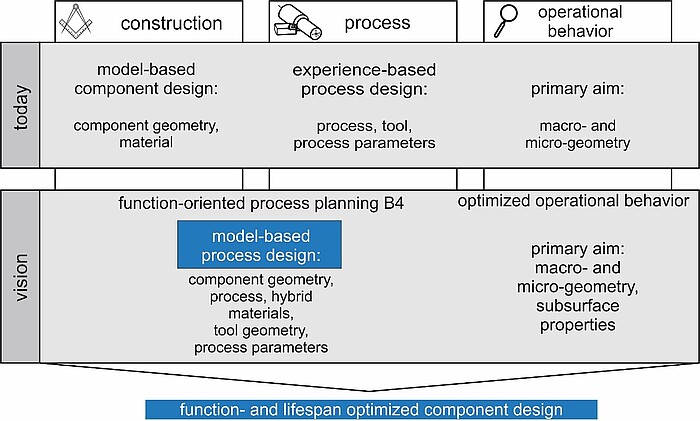

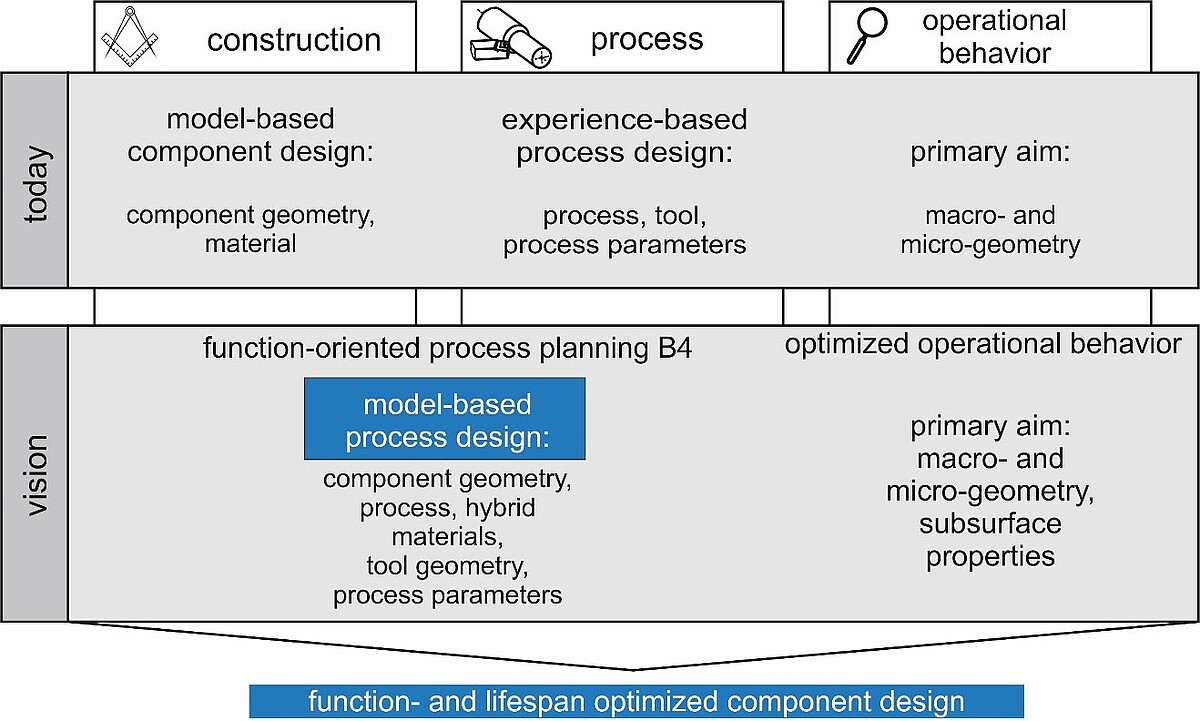

Motivation and objectives

As a surface and subsurface determining step in the process chain, machining has a significant influence on the application behaviour of solid components. Today, process planning is mostly limited to compliance with shape and position tolerances as well as roughness values. Other function-describing surface and subsurface features are currently of secondary importance. Functionally adapted process planning thus has considerable potential for improving component functionality and service life. Today, the influence of the production process on the later application behaviour and the associated potentials are hardly considered in design, since the possibilities and limits of the subsurface influencing by the final machining step, are not completely known to the designer. The basis for this are models that predict the influence of machining on surface and subsurface properties and their meaning for the application behaviour. Current models do not take a sufficient account of the interactions between component topography and subsurface on the one hand and application behaviour on the other. A comprehensive consideration of these properties in the component design for the optimization of the component application behaviour and its service life does not exist so far. Particularly in the case of hybrid components, there is a need for research for the possibilities and limits of influencing the application behaviour by machining processes. Therefore the overall goal is to create a method for process planning in metal-cutting production processes for setting function-specific surface and subsurface properties of hybrid components.

Results

In the first funding period, the fundamental interrelationships of surface and subsurface influenced by machining processes were investigated by using an example of materials for function-oriented process planning.

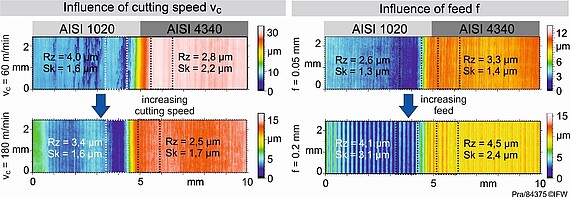

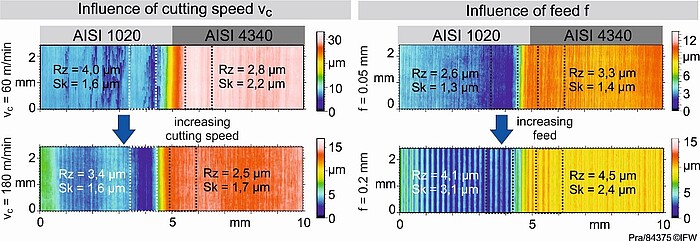

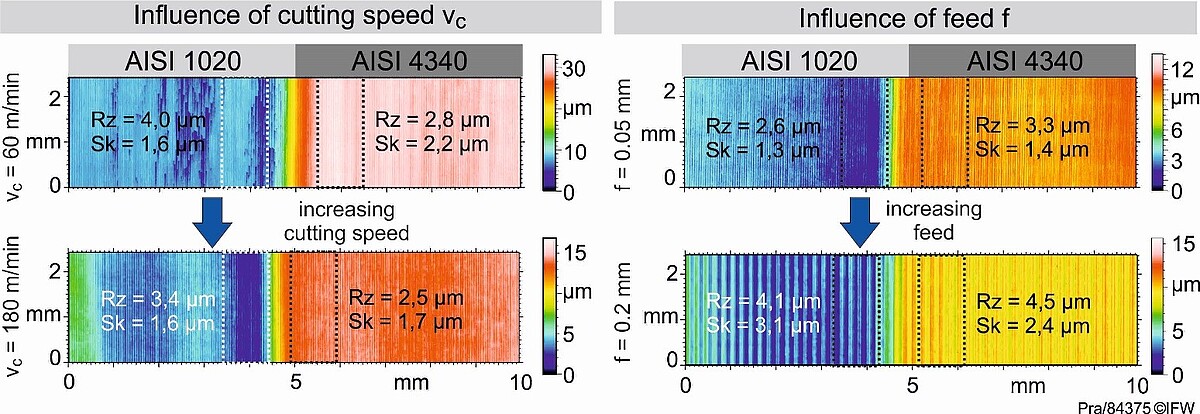

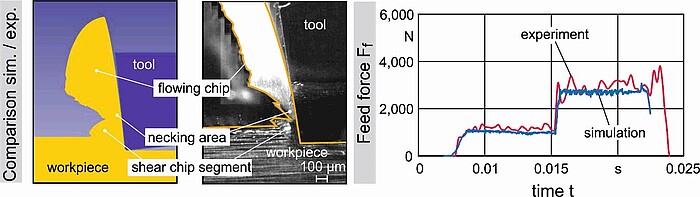

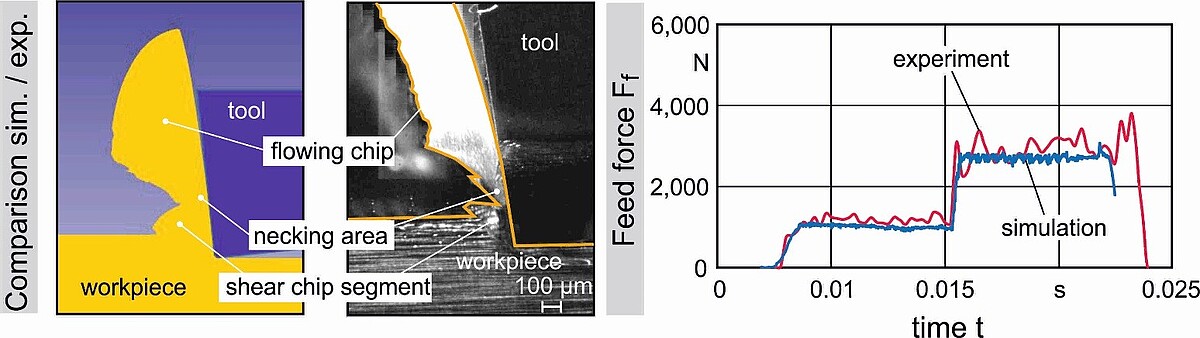

The analysis of subsurface properties in the area of the material transition zone in hybrid components posed a particular challenge. Therefore, a combination of experimental and simulation-based work was necessary. The effects on chip and surface formation as well as the influences on the resulting microstructure and residual stress development were investigated on the individual materials firstly and afterwards transferred to hybrid components. The non-destructive energy dispersive X-ray method for the measurement of residual stress depth profiles up to a material-specific information depth can be applied in a laboratory environment. The input of significant process parameters, which influence the surface and subsurface properties, both in the mono-material and in the material transition area, were identified. The residual stresses are mainly influenced by the cutting edge microgeometry, while surface roughness is also significantly influenced by the feed rate (Fig. 3).

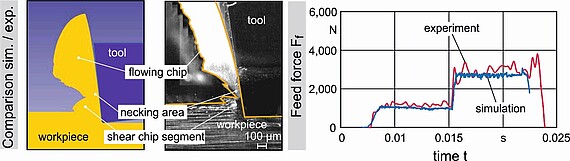

Thermal and mechanical stress fields were represented by a chip formation simulation and maximum temperature and stress effects were identified as a function of the process parameters (Fig. 4). A correlation between these effects and the resulting subsurface properties was verified. Rotating bending tests as well as rolling strength investigations in cooperation with the subproject C03 enabled the identification of life-determining surface and subsurface properties. The material characterizations carried out together with the subprojects A01 and A02 form the basis of a cross-process understanding of the component properties resulting from the manufacturing process.

Results

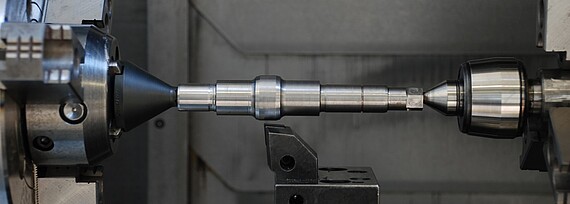

In the second funding period the investigations concerning the influence of subsurface properties on structural strength and service life of hybrid components will be deepened (Fig. 5). The results of the first funding period and the overall objective of subproject B04 raise technological questions regarding the methodology of load-adapted process planning on the one hand, and on the other hand there are open aspects regarding the deepening and integration of the findings into new material combinations and the application behaviour. Deep rolling is particularly suitable as an introduction in understanding the relationships between material load and modification, because in this process mainly the mechanical material load is existing. Near the transition areas (joints) of hybrid components, or locally adapted in the case of components made of a monomaterial, it is necessary to adapt the rolling pressure highly dynamically. Previously used rolling tools are too slow for this application. Therefore, a new tool development is being promoted that delivers the required dynamic pressure variation. To enlarge the property window with regard to roughness and residual stresses, the deep rolling process is first applied to hybrid specimens.

For the required application behaviour, favourable material-specific residual stress depth profiles as well as the optimum of residual stresses in the joining zone must be determined. It must be investigated whether residual stresses in deeper component areas increase the structural strength of extruded shafts. Starting from the deep rolling process, an inverse process modelling with the initial value "service life" is carried out. The interdisciplinary cooperation with the other subprojects of the CRC is of decisive importance for the successful completion of the project.

Publications

Subproject leader

30823 Garbsen

30823 Garbsen

30823 Garbsen

30823 Garbsen

Staff

30823 Garbsen

30823 Garbsen